Asset Integrity Engineering (AIE): An Innovative and Structured Approach to Methane Emissions Monitoring and Reduction

Asset Integrity Engineering

(AIE)

is supporting oil and gas operators with their emission reduction efforts. AIE’s staged approach

incorporates technical guidance developed by the Climate and Clean Air Coalition Oil and Gas Methane Partnership (OGMP) to assess nine core methane emission

sources. Using its proprietary Veracity software, AIE identifies areas with significant methane

emissions through desktop screening of the facilities and creates inspection plans that use

optimized infrared (IR) imaging to validate leaks. Once methane emissions are validated through

inspection, the team develops and implements an action plan for emissions reduction and monitoring.

Currently, AIE supports oil and gas facilities in the Middle East and North Africa (MENA) region and

intends to expand the use of this approach globally.

Asset Integrity Engineering

(AIE)

is supporting oil and gas operators with their emission reduction efforts. AIE’s staged approach

incorporates technical guidance developed by the Climate and Clean Air Coalition Oil and Gas Methane Partnership (OGMP) to assess nine core methane emission

sources. Using its proprietary Veracity software, AIE identifies areas with significant methane

emissions through desktop screening of the facilities and creates inspection plans that use

optimized infrared (IR) imaging to validate leaks. Once methane emissions are validated through

inspection, the team develops and implements an action plan for emissions reduction and monitoring.

Currently, AIE supports oil and gas facilities in the Middle East and North Africa (MENA) region and

intends to expand the use of this approach globally.

AIE’s Staged Approach to Methane Emission Reductions

AIE’s staged approach consists of four stages, as described below. Sample tables and charts that are used during each stage are provided as examples.

- In the Desktop Screening stage, AIE conducts a study of the facility to evaluate the presence of nine core methane emission sources with reference to the OGMP technical guidance documents, quantify the facility’s potential methane emissions, and generate an IR imaging inspection plan based on system criticality.

Example: Identification of Nine Core Elements

| Core Emission Source | Identified (✓/✗) |

|---|---|

| Natural gas-driven pneumatic controllers and pumps | ✗ |

| Fugitive component and equipment leaks | ✓ |

| Centrifugal compressors with “wet” (oil) seals | ✓ |

| Reciprocating compressors rod seal/packing vents | ✓ |

| Glycol dehydrators | ✓ |

| Unstabilized hydrocarbon liquid storage tanks | ✗ |

| Well venting for liquids unloading | ✓ |

| Well venting/flaring during well completion for hydraulically fractured gas | ✗ |

| Casinghead gas venting | ✗ |

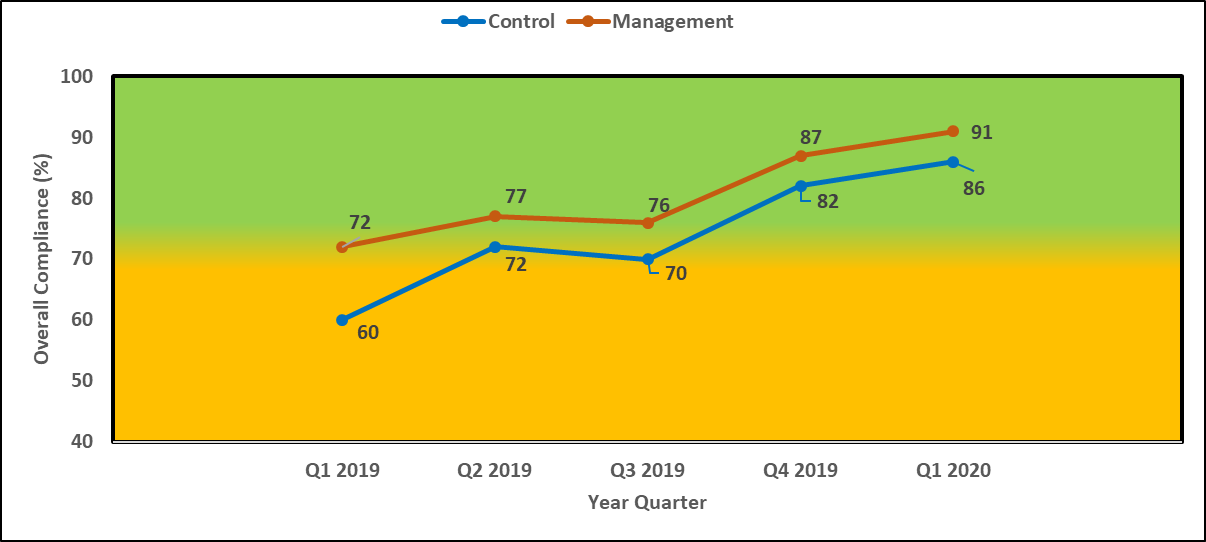

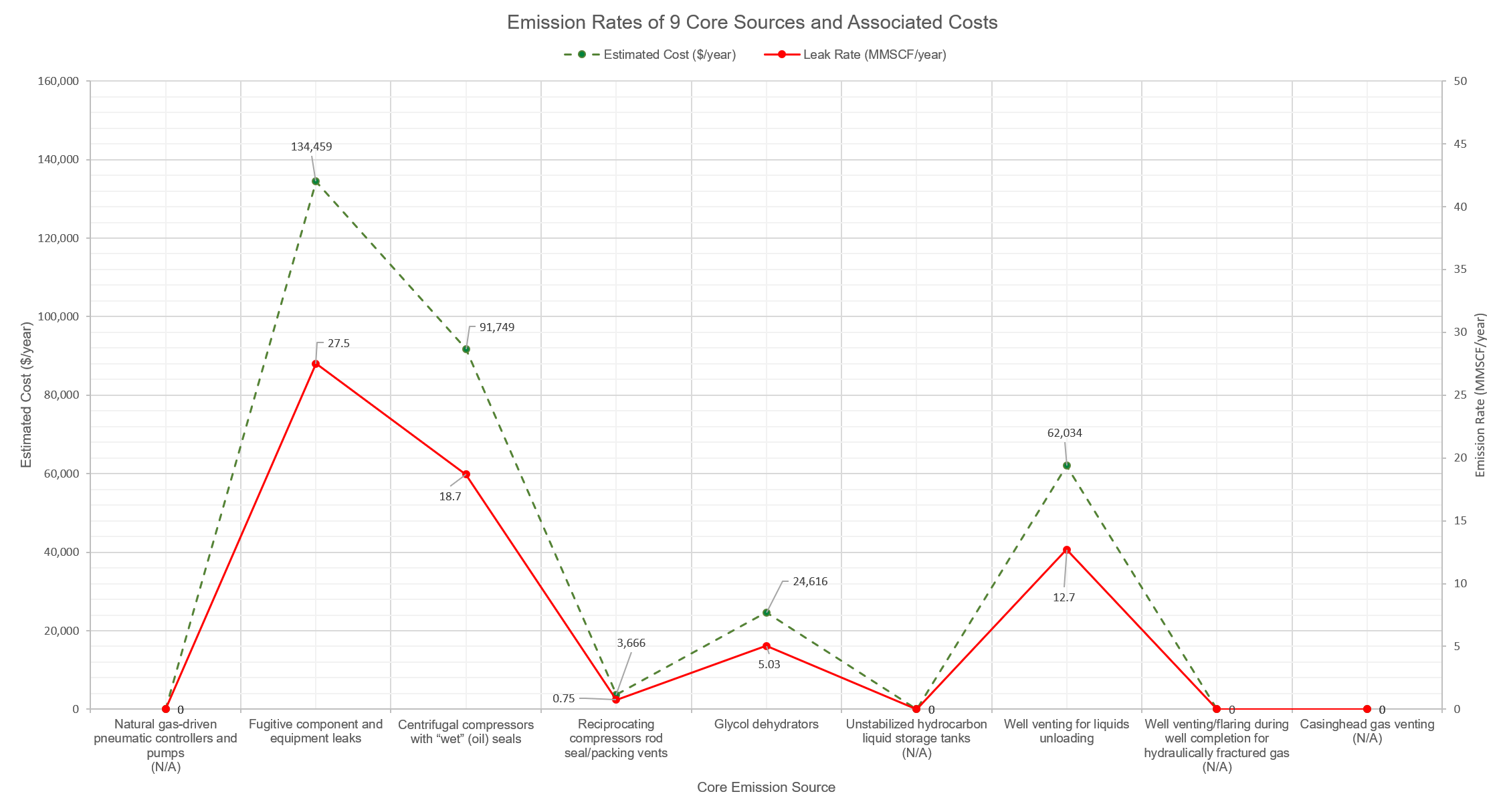

Example: Quantification of Potential Emissions

Click to enlarge the image

Example: Ranking of Criticality of Systems

| System | Pressure Score | Degradation Score | Methane Content Score | Criticality Score | Inspection Frequency (Months) |

|---|---|---|---|---|---|

| Inlet Coolers & Separators | 2 | 2 | 3 | 12 | 36 |

| Inlet Compression | 3 | 2 | 3 | 18 | 12 |

| Molecular Sieve System | 3 | 2 | 3 | 18 | 12 |

| LPG Plant | 3 | 2 | 2 | 12 | 36 |

| Condensate Plant | 2 | 2 | 1 | 4 | Opportunity Based |

| Amine Plant | 2 | 2 | 2 | 8 | Opportunity Based |

| Sales Gas | 3 | 2 | 3 | 18 | 12 |

| Propane Treater | 2 | 2 | 1 | 4 | Opportunity Based |

| Hot Oil System | 1 | 2 | 0 | 0 | Not Required |

| Reinjection System | 3 | 2 | 3 | 18 | 12 |

| Fuel Gas System | 2 | 2 | 3 | 12 | 36 |

| Flare Header System | 1 | 2 | 2 | 4 | Opportunity Based |

| LPG Terminal | 2 | 2 | 1 | 4 | Opportunity Based |

| Condensate Terminal | 2 | 2 | 1 | 4 | Opportunity Based |

| Field Manifolds and Pipeline Networks | 2 | 2 | 2 | 8 | Opportunity Based |

| Field-1 | 2 | 2 | 2 | 8 | Opportunity Based |

| Field-2 | 2 | 2 | 2 | 8 | Opportunity Based |

| Full Field Compression | 2 | 2 | 2 | 8 | Opportunity Based |

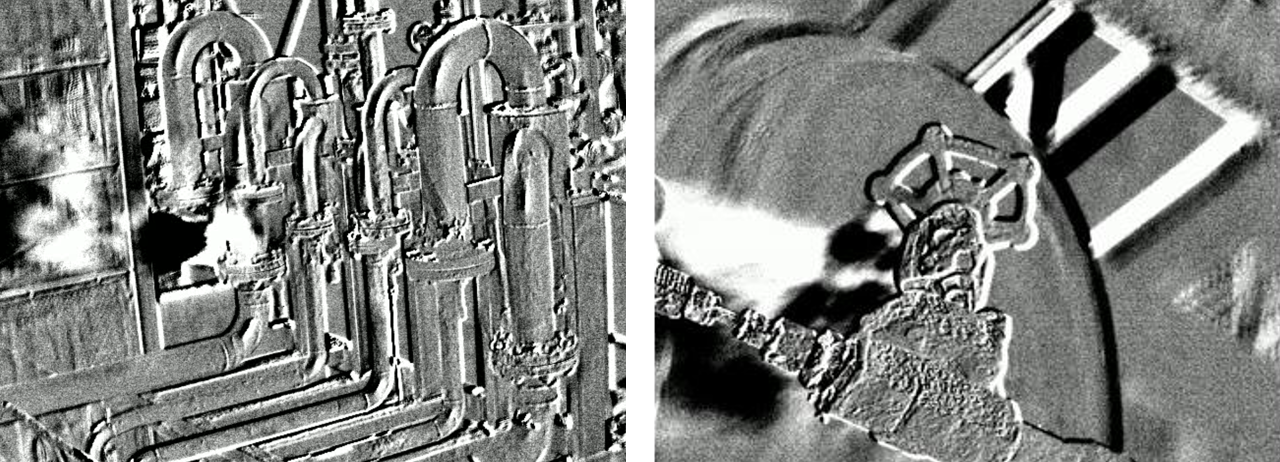

- During the Site Validation stage, AIE implements the IR imaging inspection plan and determines the actual methane emission rates. During this stage, AIE uses quantifications to verify and update estimates made during the Desktop Screening stage.

Example: IR Imaging of Leaks

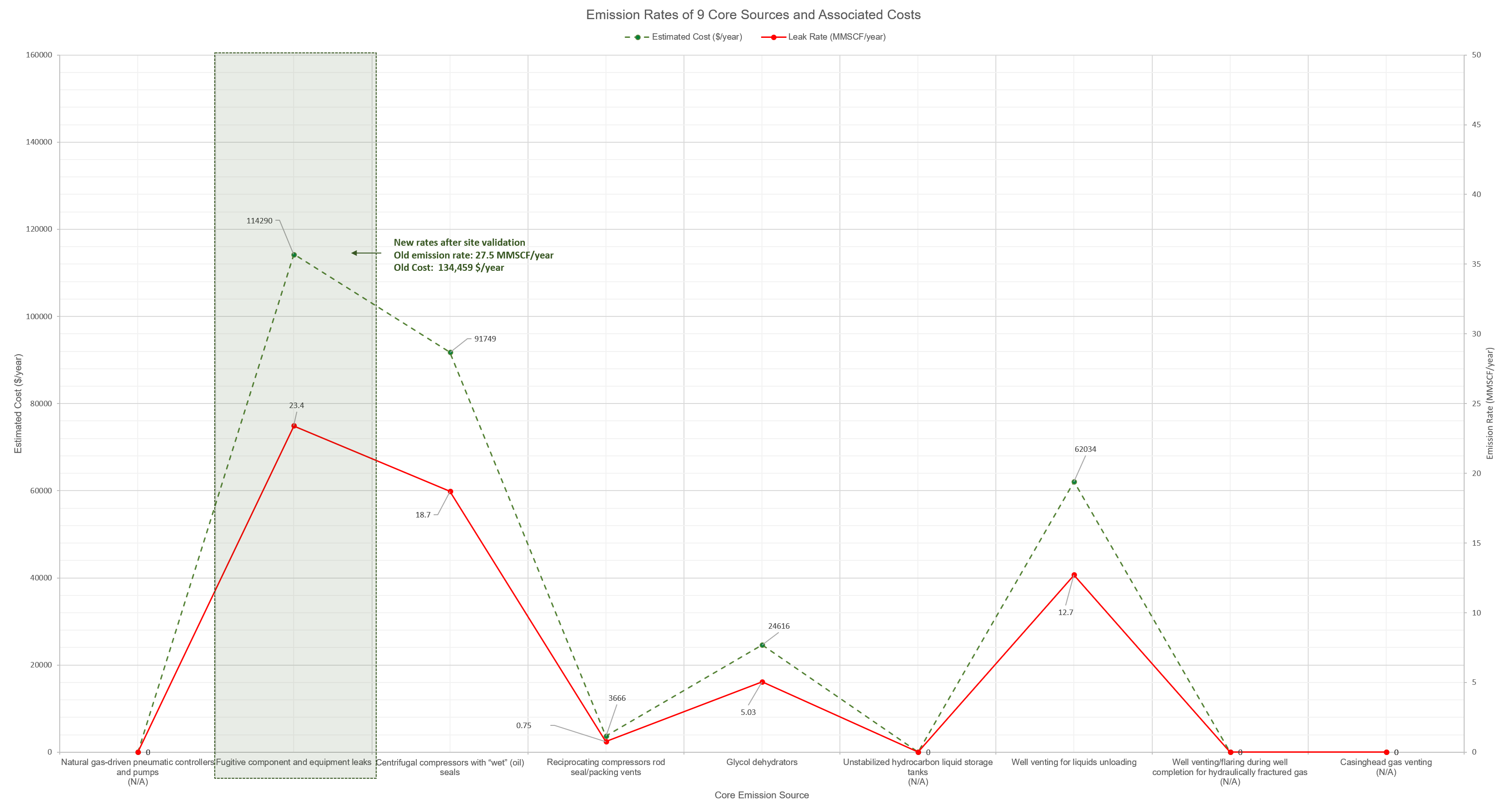

- In the Action Plan Development stage, AIE identifies and selects mitigation actions based on a cost-benefit analysis.

Example: Validated Emission Reduction Opportunities and Costs

Click to enlarge the image

- During the Action Plan Close Out, Reporting & Management stage, AIE implements Directed Inspection and Maintenance (DI&M) plans via the computerized maintenance management system. AIE sets key performance indicators and monitors and reports action items using the Veracity software. For example, the percentage of overall compliance for the control system, with no emission management, is compared to the percentage of overall compliance of the system using AIE’s emissions management approach.

Example: Performance Indicator Measurement